In many energy and commodities organisations, sophisticated CTRM and ETRM systems confidently tell the business what has happened or what should have happened. Yet the physical world often tells a different story. A shipment marked as “departed” may still be sitting in port; a planned outage may not be fully reflected in trading positions; a refinery constraint may never reach the desks of analysts who need it most. This disconnect between digital processes and physical reality is one of the industry’s most persistent blind spots.

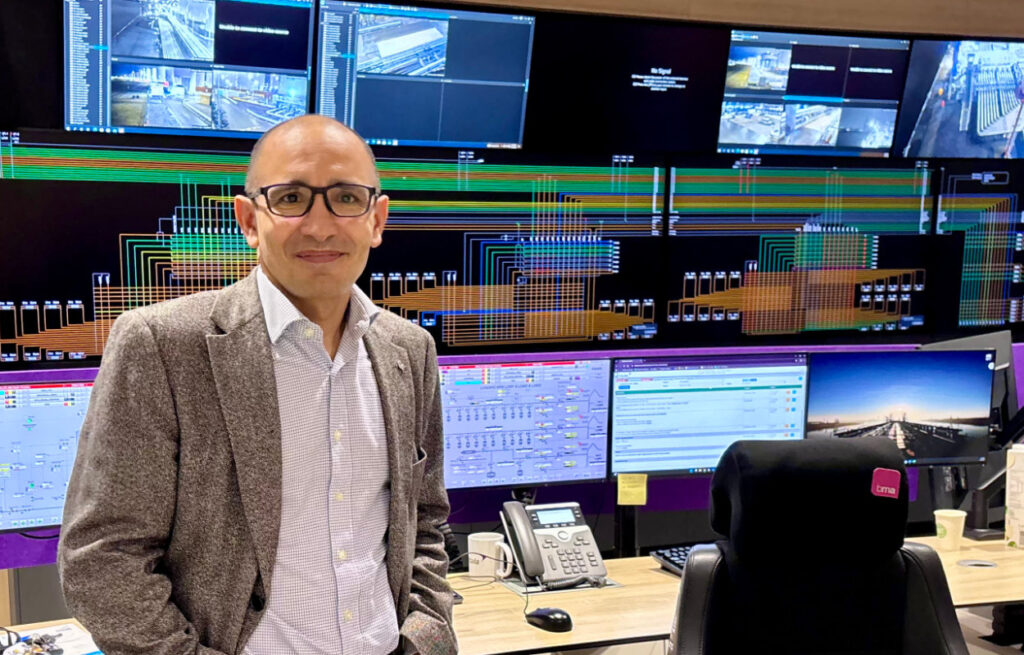

To explore this challenge, we spoke with Josep Serrano, an expert who has spent his career operating at the intersection of industrial IT, OT, and trading systems. His experience spans power plants, refineries, logistics operations, and enterprise technology — giving him a rare, end-to-end perspective on why integration remains so difficult and what must change.

The invisible foundation behind every trade

Business systems such as C/ETRM, ERP, and CRM are the main drivers of operational efficiency and strategic decision-making. These systems provide dashboards, analytics, and workflows that guide traders and executives in managing complex portfolios, risk, contracts, and financial transactions.

Yet behind every transaction and decision lies a vast industrial foundation that is often overlooked: mines, refineries, pipelines, power plants, warehouses, vessels, railcars, and trucks.

Behind every trade lies a network of operational technology and industrial systems that control, monitor, and automate physical processes – many of which are legacy, siloed, or only partially integrated. These blind spots can compromise data accuracy, risk assessment, and real-world decision-making.

While business systems deliver insight and decision support, they are entirely dependent on accurate, timely, and complete data and processes from the OT (Operational Technology) and the industrial systems.

The Cost of Neglecting Industrial Systems

Many organisations neglect this industrial layer. Legacy systems remain in place for years or decades, often partially integrated at best. This creates blind spots: a trade booked in a CTRM may assume that a shipment has departed, yet without real-time integration with logistics tracking or plant operations, there is no guarantee that the physical transaction has occurred as expected.

Decisions made on incomplete or delayed data can lead to operational inefficiencies, financial miscalculations, and regulatory noncompliance – risks that are amplified in energy and commodity markets, where margins are tight and timing is critical (just think demurrage costs).

IT Must Speak the Language of Operations

Josep believes the future of technology in commodities requires a fundamental shift: IT teams must understand the operational realities behind the data they manage.

Companies must invest in modernising legacy industrial systems, improving integration across IT and OT, and ensuring end-to-end visibility from the plant floor to the boardroom.

“In my view, it is critical to understand, modernise, and fully integrate OT and industrial systems to achieve reliable, end-to-end visibility.”

IT departments must transform to deal with industrial infrastructure and automation systems that enable real-time control, monitoring, and data collection from physical assets, including OT, SCADA, MES, and IoT solutions.

Beyond technology, IT professionals must now also understand the value chain in detail – how commodities and energy move from production through logistics to market. With this dual perspective, they can design integrations that are not only technically sound but also aligned with operational realities. It is a shift that places business processes and value creation at the core of technology.

Cross-Functional Teams Bridge the Divide

To bridge this gap, organisations should deliberately mix cross-functional teams that bring business and operational expertise into the IT function. Subject matter experts from trading, logistics, plant operations, and risk management understand the practical realities of how commodities and energy flow across assets and markets.

Their insights are critical not only for designing business systems that reflect real-world processes instead of abstract assumptions, but also for operating these systems effectively in the long run.

By embedding these experts in cross-functional teams, companies ensure that business systems, industrial IT, and OT remain technically sound, relevant, and aligned with business goals.

Integration Beyond Company Boundaries

End-to-end integration doesn’t stop at your company’s edge. Trading is a network, and systems must behave like one. Even in vertically integrated companies, operations rarely occur without engaging external partners. Transactions, logistics, and risk management frequently involve multiple partners, suppliers, and service providers.

This external dimension adds complexity to achieving true end-to-end integration: business systems, industrial IT, and OT must not only communicate internally but also securely exchange accurate, timely data across company boundaries.

Achieving this requires a shift away from proprietary protocols and custom interfaces toward more flexible, standardised, and secure integration approaches.

Today, companies can leverage secure APIs, web services, encrypted file transfers, and even blockchain transaction ledgers to move information seamlessly across systems and organisational boundaries.

A Path Forward

In summary, achieving reliable, end-to-end integration requires a holistic approach that goes beyond business systems alone. Companies must modernise legacy industrial and OT systems, adopt secure and standardised methods for exchanging information, and embed cross-functional expertise into IT teams.

By combining real-time industrial data, operational knowledge, and flexible technology standards such as APIs, web services, and blockchain-based transactions, organisations can ensure that business systems are not only technically robust but also aligned with operational realities.

The views expressed in this article are my own and do not necessarily reflect those of my employer or any affiliated organisations.

Looking for more insights?

Get exclusive insights from industry leaders, stay up-to-date with the latest news, and explore the cutting-edge tech shaping the sector by subscribing to our newsletter, Commodities Tech Insider.